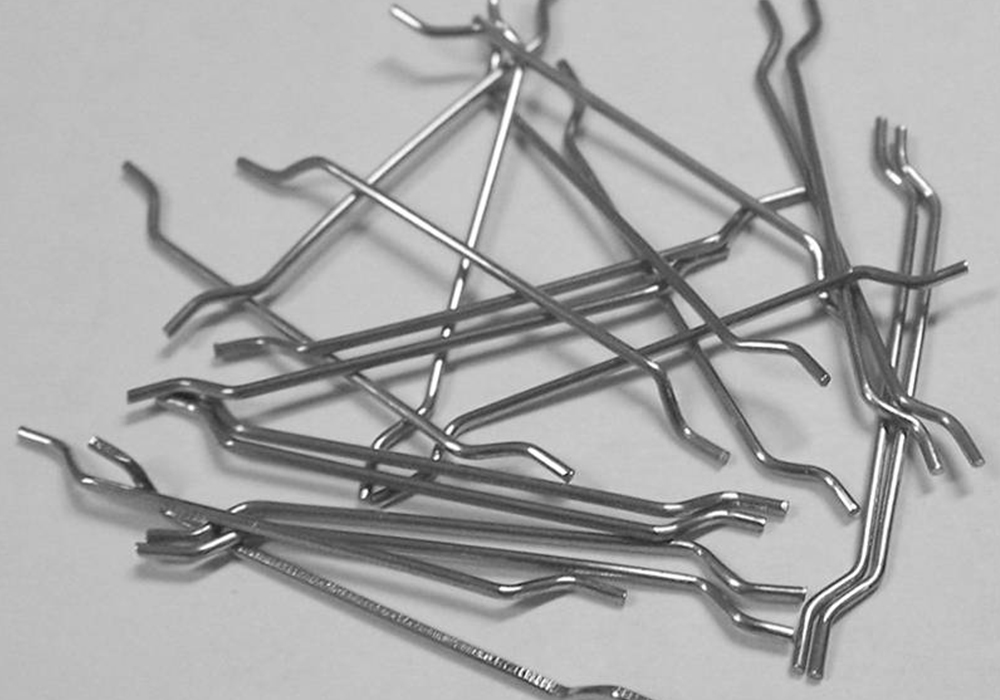

Steel fibers for industrial floors, sprayed concrete and tunnels

Concrete reinforcement by adding steel fibers to sprayed concrete in tunnels precludes the need to use expensive molds and complex castings, thus allowing saving of expensive resources.

Main applications:

The advantages of using steel fibers:

Steel fibers definition:

| Fiber according to the flooring characteristics | Tensile strength (MPa) | Length (mm) | Diameter (mm) | Length / diameter ration (aspect ratio) | Number of fibers per KG |

|---|---|---|---|---|---|

| Steel fiber for flooring without racking system | 1100 | 50 | 1.00 | 50 | 3200 |

| Steel fiber for flooring of logistical centers | 1100 | 50 | 0.75 | 67 | 5700 |

| Steel fiber for shotcrete | 1200 | 35 | 0.55/0.75 | 67/80 | 5200 |

| Steel fiber for heavy-duty industrial flooring | 1200 | 60 | 0.9 | 67 | 4800 |